With 146 million tons of vegetables and 75 million tons of fresh fruits per annum produced in the country, it becomes a challenging job for logistics to maintain a fresh supply chain. With fresh products having short shelf life and being perishable, bulky, and seasonable, marketing of fruits and vegetables is much more difficult. Running a logistics for fresh products in a country as big as India, with increasing demand, asks for a well-maintained supply chain. With all the challenges come various opportunities for the same.

The article in the following points discusses the conditions for Logistics and Supply Chain Management to optimize the transport of fruits and vegetables much faster and more-fresh.

1. MINIMIZING THE TIME: FAST TRANSPORTATION

To minimize transportation time and achieve maximum efficiency for the perishable product transportation, it is important to monitor supply chain control. Recognizing and practicing more control of the end-to-end value chain is a primary concern to achieve faster deliveries. To attain ascendance over the whole supply chain, fresh supply chain leaders are attaining the method of VERTICAL INTEGRATION, where a large supermarket chain is directly active in production methods such as farming. This ensures quick transportation service throughout.

2. VISIBILITY

To ensure maximum productivity in fast and fresh transportation, it is important to maintain visibility across the supply chain. Implementation of the Transport Management System (TMS) and Warehouse Management System (WMS) ensures better visibility. With these tools, warehouse activities can be improved and labor planning is done effectively. Poor supply chain visibility results in delayed deliveries which leads to shrinkage of perishable goods, and in many cases, failure to even reach the store shelves

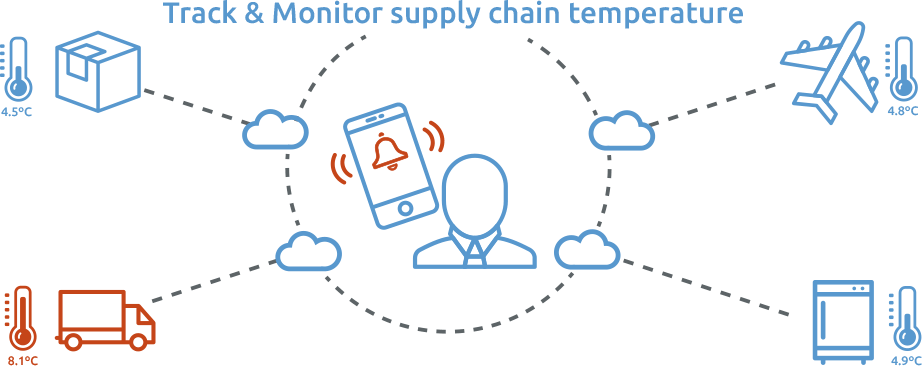

3. TEMPERATURE CONTROL

Perishable and fresh food supply chains can maintain quick deliveries up to a certain possible level. Here, temperature control plays a major role to keep the chain running efficaciously. An ‘Unbroken Cold Chain’ from producer to store is a vital aspect for the same.

The cold chain focus areas are as follows:

Technology to monitor control of the temperature in processing and transport.

Leveraging human capital for fresh product transportation.

Third-party logistics specialists utilization accordingly.

4. USE OF TECHNOLOGY

The temperature-sensitive produce requires a certain mandatory block of temperature during transportation. This implementation requires the usage of certain technologies. To ensure a suitable temperature for different products, the methods used are as follows:

RFID tags – record real-time temperature data and forward the same to product suppliers.

Real-time GPS tracking – to provide visibility for shipment advancement.

Active monitoring solutions – adjust according to a suitable temperature in the sudden event of fluctuations

Passive monitoring – provide historical shipment data.

These are the primary methods to improve your fresh supply chain. Traceability, visibility, and modern methodologies play a vital role in maintaining a fresh chain. The roadmap to your supply chain progression can be followed through these main points.

With all the challenges, Fresh Supply Chains provide many opportunities in the ever-increasing demanding population of the country.